Timber has long been a staple of construction, but in the era of net-zero energy goals and low-carbon development, timber beams are making a serious comeback. As buildings get smarter and greener, timber offers a structural solution that meets both performance demands and sustainability benchmarks.

In this article, we examine timber’s capabilities through the lens of structural engineering, construction efficiency, environmental impact, and cost-benefit analysis. Along the way, we’ll present key data and real-world examples that show how timber is not just relevant it’s revolutionary.

Expanded Insights on Timber Engineering and Applications

To fully appreciate timber’s potential, it’s crucial to explore its adaptability in building systems ranging from small residential projects to high-rise commercial developments. Engineered wood products like LVL, CLT, and glulam are not only stronger than traditional lumber, but also more reliable under load and better suited to modern construction workflows.

Key Insight: Redbuilt reports that engineered wood consumption in North America has increased by 60% over the past decade, a testament to its growing role in structural applications.

These engineered products can be customized for nearly every load-bearing or spanning scenario, often replacing steel beams in places where weight and thermal bridging would otherwise compromise performance. For example, CLT panels can be used as floor slabs, shear walls, or even roof decking, thanks to their high dimensional stability.

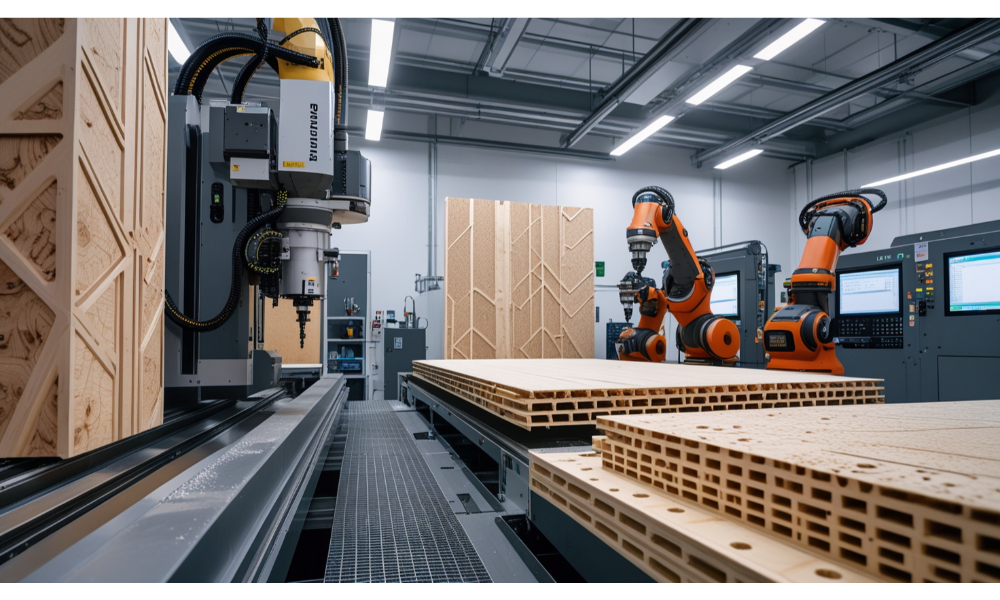

Timber’s strength and rigidity are further enhanced by modern fabrication methods like finger-jointing, pressure laminating, and CNC milling, allowing greater spans with fewer supports and more open-plan layouts.

The versatility of timber also plays out in its use for bridges, stadiums, and civic buildings. Its high strength-to-weight ratio simplifies design for long spans, while its visual appeal supports cultural identity and place-making. Architects around the world are increasingly designing civic spaces with exposed frameworks made from timber, highlighting its ability to blend functionality with symbolism.

Timber construction is also pushing the boundaries of height and complexity, supported by research in hybrid systems where timber is combined with steel or concrete to achieve optimized structural and environmental performance. These hybrid methods often outperform single-material solutions in life-cycle cost and energy usage.

The Broader Ecosystem: Timber in Modular and Passive Design

Timber beams are also ideal for integration into modular construction a sector growing at 6.5% annually globally. Modules framed with timber are lighter, easier to transport, and faster to assemble on site. This is especially important in disaster-relief housing and remote or rural developments.

Timber modules have been used to build hospitals in under 30 days, classrooms within weeks, and pop-up urban infill projects with almost zero on-site emissions. Their flexibility allows architects to stack, shift, and shape volumes with minimal delay.

Passive House standards also favor timber due to its insulating properties and low thermal bridging. Combined with high-performance glazing and insulation, timber frameworks enable ultra-low energy use.

According to Passive House Institute US (PHIUS), buildings using mass timber panels achieve air changes per hour (ACH50) below 0.6, indicating exceptional airtightness. As energy codes tighten globally, timber assemblies make it easier to meet or exceed performance thresholds.

Timber panels also support factory-sealed insulation, eliminating common performance gaps in traditional framing. With pre-cut openings and chase routes, MEP integration is smoother and quicker, allowing more accurate coordination during construction. This precision significantly reduces change orders and schedule delays.

Workforce Impacts and Innovation in Timber Construction

Beyond materials, timber is driving innovation in workforce training and construction technology. Carpentry apprenticeships are being redesigned around mass timber handling, digital fabrication, and robot-assisted assembly. Educational institutions like BCIT and MIT now offer curricula focused on timber engineering and pre-fabrication techniques.

Interesting Stat: A report from WoodWorks found that the use of digital tools like 3D modeling, CNC cutting, and parametric design reduced construction errors in timber projects by up to 40%.

Digital fabrication enables millimeter-accurate cuts and assemblies, dramatically improving construction predictability. It also allows for new architectural forms curved spans, perforated beams, or artistic elements that are costly or impractical with conventional materials.

On-site teams benefit from better ergonomics due to timber’s light weight, reducing injury rates. Prefabricated joisting and decking systems also lessen the exposure to hazardous environments, improving safety compliance. Pre-drilled beams and embedded hardware reduce the need for on-site drilling and welding, speeding up installation by as much as 35%.

In large timber projects, up to 30% fewer workers are needed on site, helping firms adapt to labor shortages. With digital integration, teams can validate connections and simulate assemblies before lifting a beam, enhancing productivity. The integration of augmented reality (AR) and drones for inspection and coordination is further accelerating adoption.

Policy and Market Demand: Timber’s Strategic Value

Governments are taking note. France has mandated that all new public buildings must be at least 50% wood or other sustainable materials by 2025. Similarly, Canada and the U.S. are investing in tall wood innovation through grants, research, and streamlined permitting.

The World Green Building Council now includes embodied carbon as a key performance indicator. Mass timber’s ability to sequester carbon and reduce material intensity aligns with these updated metrics.

Forecast: Allied Market Research predicts the global cross-laminated timber market will hit $3.7 billion by 2030, reflecting robust investor and builder confidence.

In the U.S., the Timber Innovation Act has encouraged federal agencies to pursue wood-based mid-rise and tall building projects, while jurisdictions like Oregon and British Columbia have adjusted building codes to allow taller timber structures by default.

Private developers are also leveraging ESG metrics to attract capital. Timber projects often qualify for green bonds, insurance discounts, and accelerated permitting under green infrastructure initiatives. Financial institutions increasingly recognize the material’s value in low-carbon investment portfolios.

Holistic Impact: Health, Culture, and Community

Timber is also playing a role in reshaping how buildings impact occupants and communities:

In schools, timber’s warmth and acoustic control improve student performance and well-being.

In offices, studies show a 13% increase in productivity and a 15% decrease in absenteeism.

In housing, especially affordable and transitional projects, wood supports rapid delivery and lower energy burdens.

Timber contributes to visual connection with nature, which research links to lower cortisol levels and increased satisfaction with indoor environments. Biophilic design isn’t just a trend it’s measurable in health data.

A University of British Columbia study found that wood elements in healthcare facilities reduced patient recovery time by 8% and decreased stress-related incidents by 10%.

Cultural associations with timber also play a role. Indigenous and regional design practices often prioritize wood, linking structure to tradition and resilience. In Scandinavian countries, timber is a key component of public architecture, reinforcing sustainability and cultural continuity.

Timber’s impact also extends to economic inclusion. Forestry and wood-product manufacturing support rural economies and job creation. Community-scale timber projects such as libraries, recreation centers, and mixed-income housing often catalyze civic pride and identity.

Timber in Net-Zero and Circular Construction Strategies

As the industry shifts toward circular economy models, timber is gaining further importance. Wood is naturally recyclable and adaptable. Beam offcuts can be repurposed for joinery, sheathing, or insulation support. Unlike steel or concrete, timber can be disassembled and reused with minimal energy input.

Buildings like the Circular Building in London demonstrate this with glulam beams and bolted joints that allow complete structural reuse. Panels, planks, and columns can be flat-packed and repurposed in future projects.

In lifecycle cost assessments, timber-based structures show significant savings in embodied energy and maintenance over a 60-year span, contributing to resilient investment models for municipalities and developers.

Timber buildings are also easier to adapt for future use, extending their functional lifespan. Demountable connections and modular designs allow spaces to be reconfigured or relocated without demolishing structural systems, further reducing environmental impact.

Efforts are also underway to develop bio-based coatings and fire treatments that enhance longevity without compromising recyclability. These innovations allow timber to function in increasingly complex regulatory environments while maintaining ecological advantages.

In Summary

Timber beams offer a compelling mix of performance, sustainability, and aesthetic flexibility. With the ability to span great distances, speed up construction, and cut carbon dramatically, timber is quickly becoming a core material in forward-thinking building design.

Whether applied in urban towers, rural homes, or public buildings, timber has earned its place not only as a natural resource but as a high-performance solution for the next generation of infrastructure.

By embracing innovation, prioritizing ecological responsibility, and leveraging the many structural advantages timber offers, builders and designers can construct buildings that are healthier, stronger, and better for the planet.

The renaissance of timber signals a broader shift in how we define modern construction not by synthetic materials alone, but by renewable strategies and holistic thinking that balance function, culture, and climate.

Comments are closed.