The role of molded pulp suppliers is particularly important in the world of modern packaging, where sustainability and functionality come together. These suppliers provide a versatile and eco-friendly alternative to traditional packaging materials, offering numerous benefits to businesses across various industries. From enhancing product protection to reducing environmental impact, the advantages of sourcing from reliable molded pulp suppliers are manifold and increasingly sought after in today’s market.

Molded Pulp: A Sustainable Solution

The molded pulp, derived from recycled paper and cardboard materials, is celebrated for its environmental sustainability. The process involves transforming these fibers into robust packaging through molding techniques. By using renewable resources, this environmentally beneficial strategy promotes a circular economy while also reducing waste. As businesses and consumers alike prioritize sustainability, molded pulp has emerged as a favored choice for packaging solutions.

Enhanced Product Protection And Performance

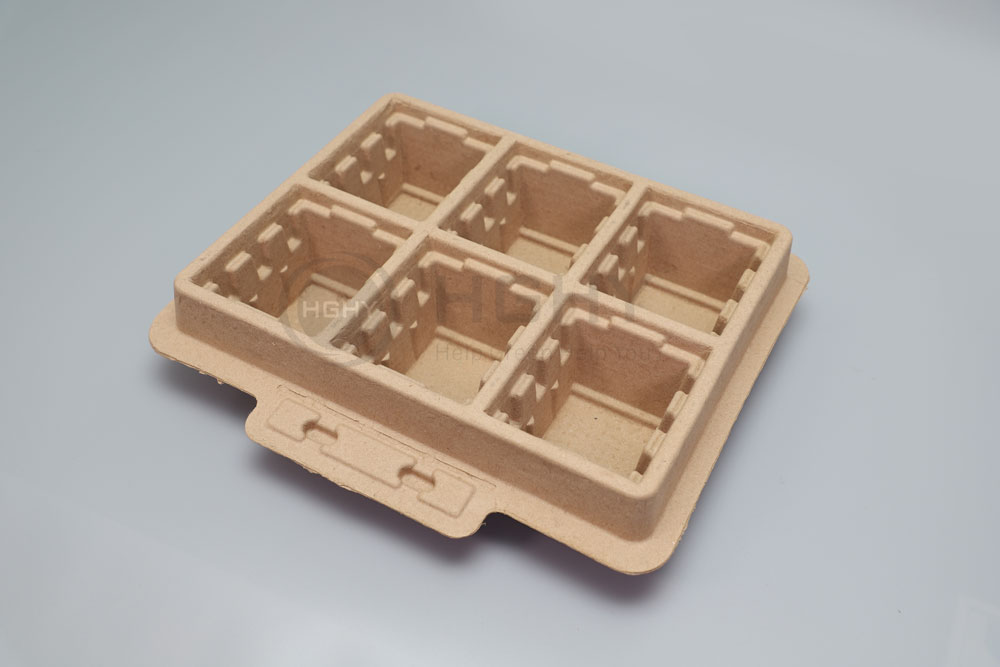

One of the primary benefits of utilizing molded pulp packaging lies in its superior protective capabilities. Molded pulp products are custom-designed to fit the contours of specific items, offering secure cushioning during transit. Whether shipping fragile electronics, delicate ceramics, or perishable goods, the inherent shock-absorbing properties of molded pulp help minimize damage and ensure products reach their destinations intact. This aspect not only reduces losses due to breakage but also enhances customer satisfaction by delivering products in pristine condition.

Versatility In Design And Customization

Another compelling advantage of partnering with reliable molded pulp suppliers is the versatility of design and customization options. Molded pulp can be molded into various shapes and sizes, accommodating diverse product requirements. Suppliers often offer bespoke packaging solutions tailored to individual products, ensuring a perfect fit and optimal protection. This flexibility allows businesses to maintain brand integrity while meeting specific packaging needs, whether for retail display, e-commerce shipping, or industrial applications.

Cost-Effectiveness And Operational Efficiency

Beyond environmental benefits and product protection, molded pulp packaging offers significant cost advantages over traditional alternatives. The raw materials used in molded pulp production are typically less expensive compared to plastics or foams. Moreover, advancements in manufacturing processes have improved efficiency, reducing production costs and making molded pulp a cost-effective choice for businesses of all sizes. Additionally, its lightweight nature can lower shipping costs and improve logistical efficiency, contributing to overall operational savings.

Compliance With Regulatory Standards And Consumer Preferences

In a time of increased environmental consciousness and strict regulations, packaging made of molded pulp is compliant with international sustainability programs and legal criteria. It meets the criteria for recyclability and compostability, supporting businesses in their efforts to adhere to environmental regulations and consumer expectations for sustainable practices. Choosing molded pulp demonstrates corporate responsibility and enhances brand reputation among eco-conscious consumers who prioritize products packaged with minimal environmental impact.

Contribution To A Circular Economy

Molded pulp packaging is essential to the advancement of the circular economy idea, which emphasizes waste reduction and effective resource use. As a biodegradable material derived from recycled fibers, molded pulp can be easily recycled or composted at the end of its lifecycle. This closed-loop approach reduces landfill waste and conserves natural resources, supporting a sustainable supply chain from production through to disposal. By embracing molded pulp solutions, businesses contribute to the broader goal of achieving environmental sustainability and reducing their carbon footprint.

Future Trends And Innovations

In terms of the future, molded pulp suppliers should expect to see constant innovation and breakthroughs in technology. Suppliers are exploring new materials, refining manufacturing processes, and expanding design possibilities to further enhance the performance and appeal of molded pulp packaging. Innovations such as water-resistant coatings and improved customization capabilities are poised to broaden the applications of molded pulp across industries, reinforcing its position as a versatile and sustainable packaging solution for the future.

Conclusion

In conclusion, the benefits of sourcing from reliable molded pulp suppliers extend far beyond traditional packaging considerations. From environmental sustainability and product protection to cost-effectiveness and regulatory compliance, molded pulp offers a comprehensive array of advantages that resonate with businesses seeking sustainable packaging solutions. In order to shape a more sustainable future for packaging, molded pulp providers will become more and more important as customer tastes and environmental awareness rise globally. By embracing the benefits of molded pulp, businesses not only enhance operational efficiency and reduce costs but also demonstrate their commitment to environmental stewardship and consumer satisfaction.

Comments are closed.